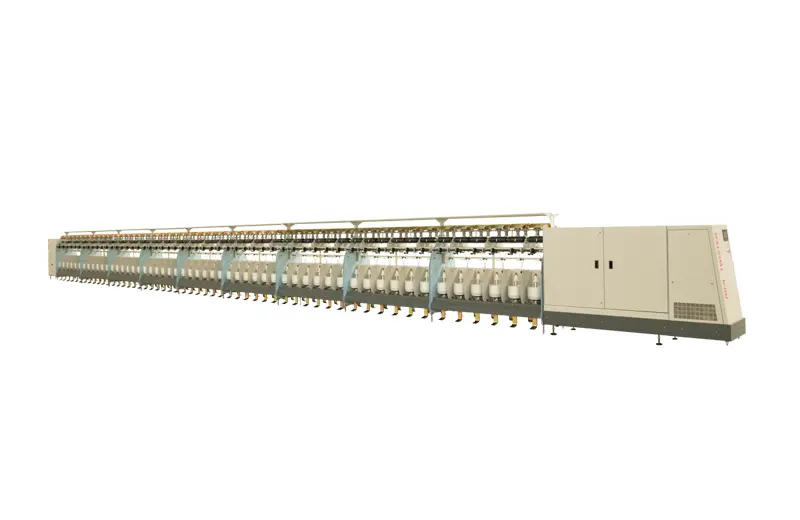

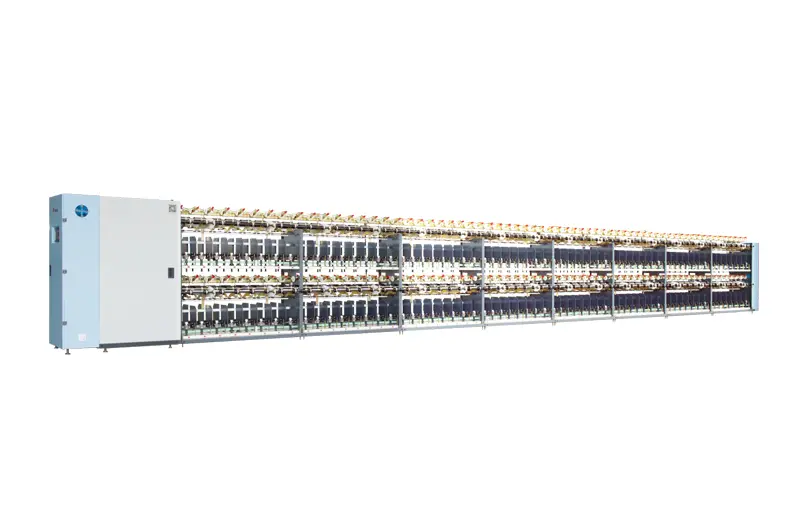

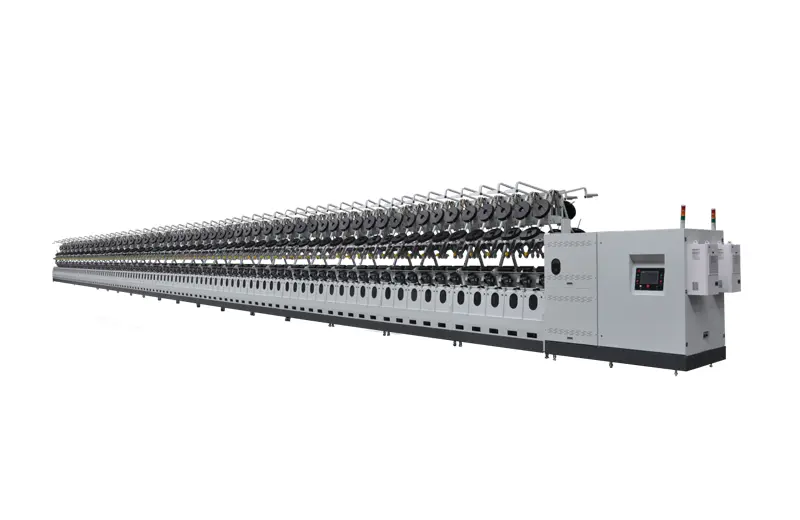

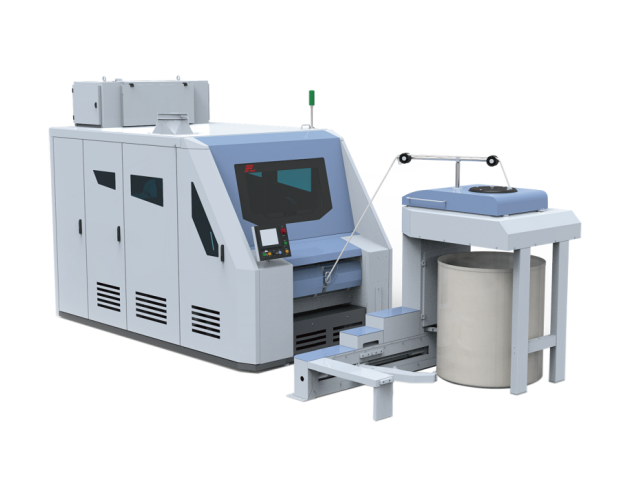

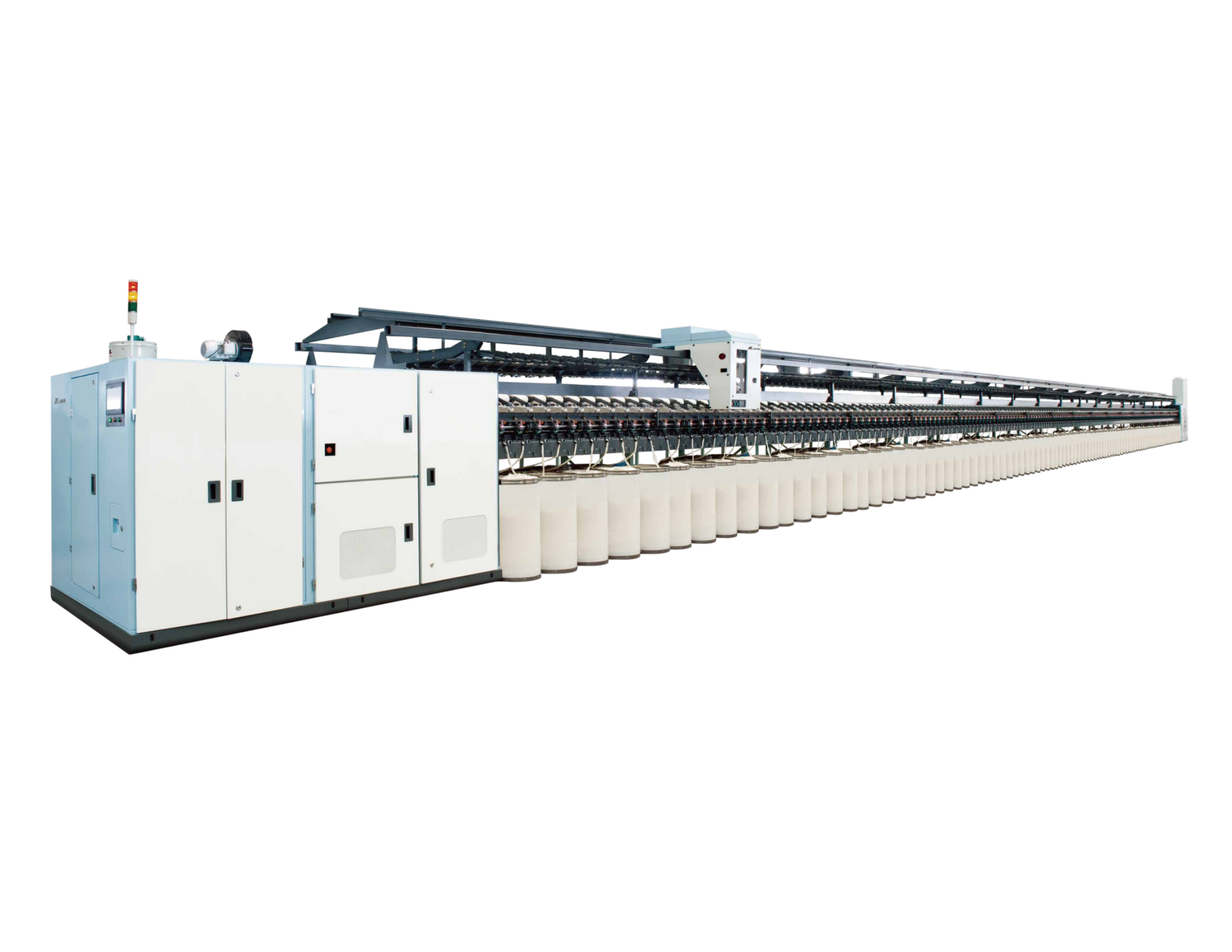

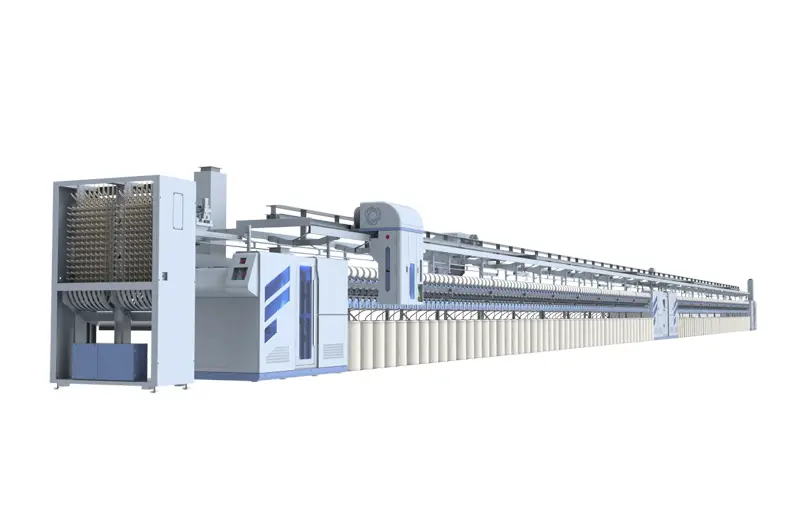

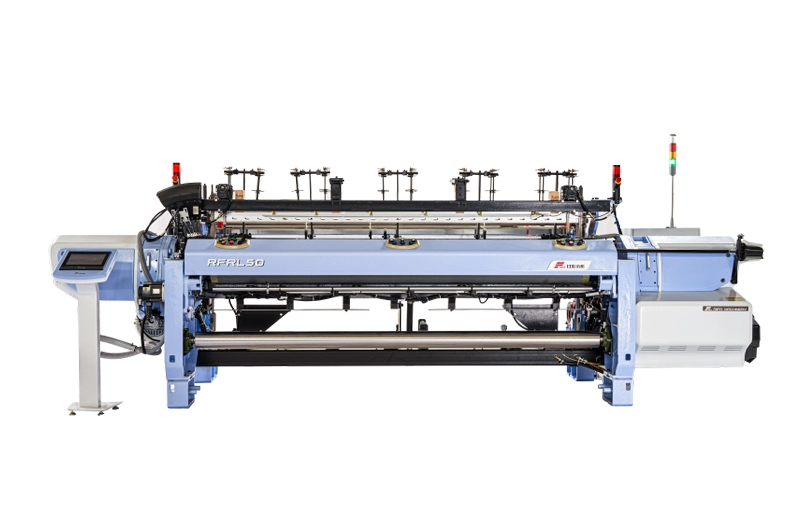

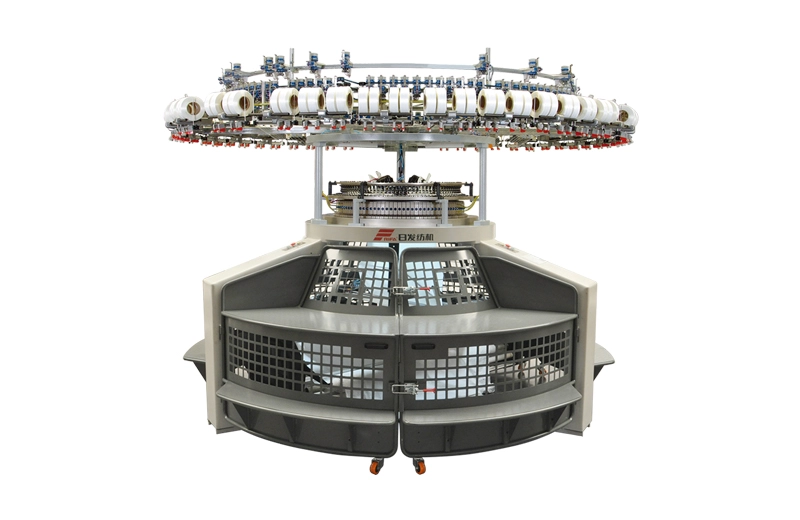

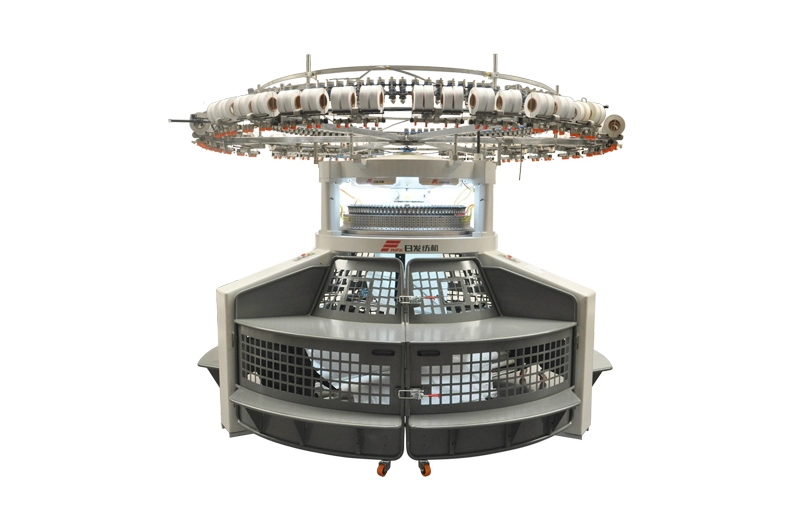

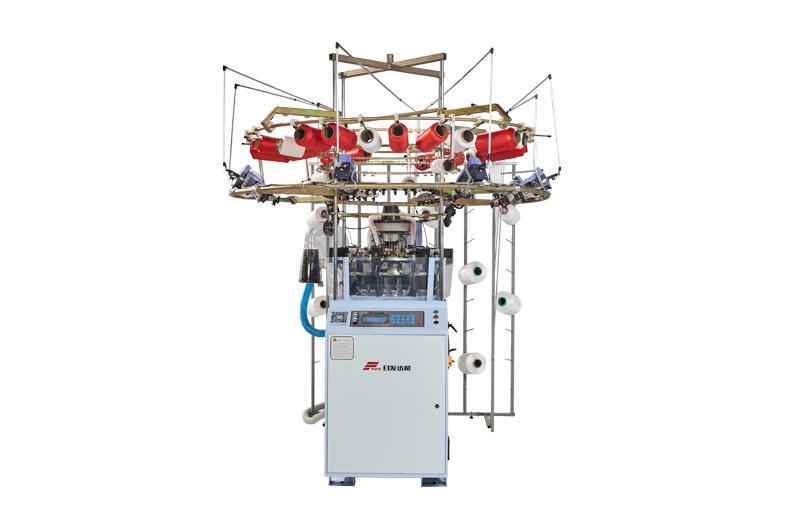

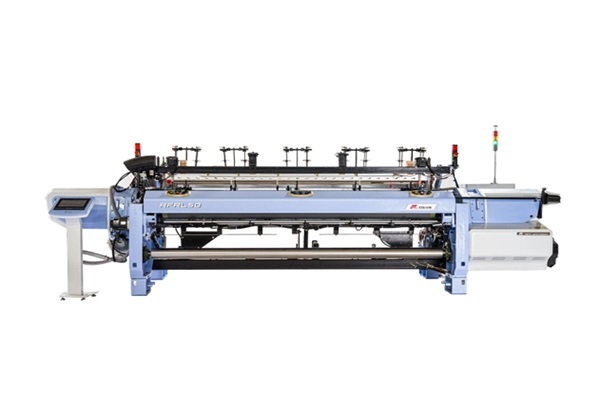

In today's textile industry, where quality, efficiency, and energy conservation are top priorities, the single twister machine plays a central role in yarn twisting. Its technological upgrades directly influence yarn strength and the quality of finished products. As a leading national high-tech enterprise in China, Rifa Textile Machinery has developed advanced electric spindle single twister machine—such as the RFTI11 model—integrating world-class technologies from Schneider, Siemens, and more. This article explores the operating principles, technical strengths, and how Rifa's innovations help textile manufacturers boost productivity.

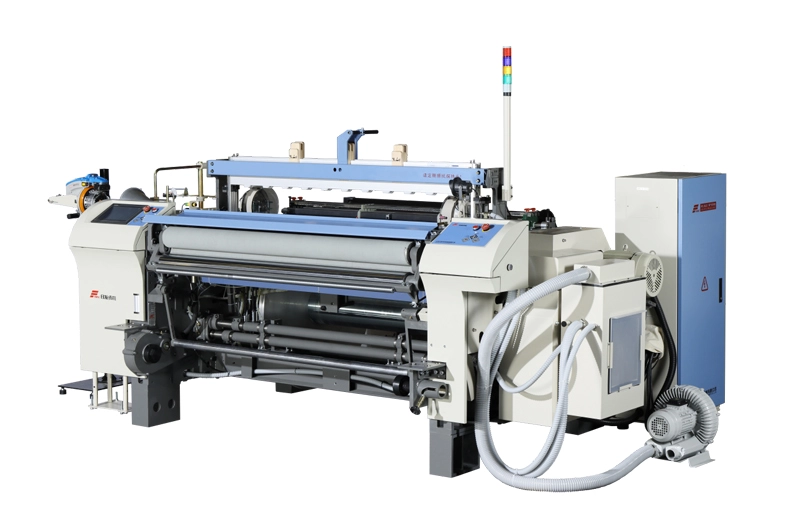

The Core Difference Between a Single Twister Machine and Traditional Twisting Technology

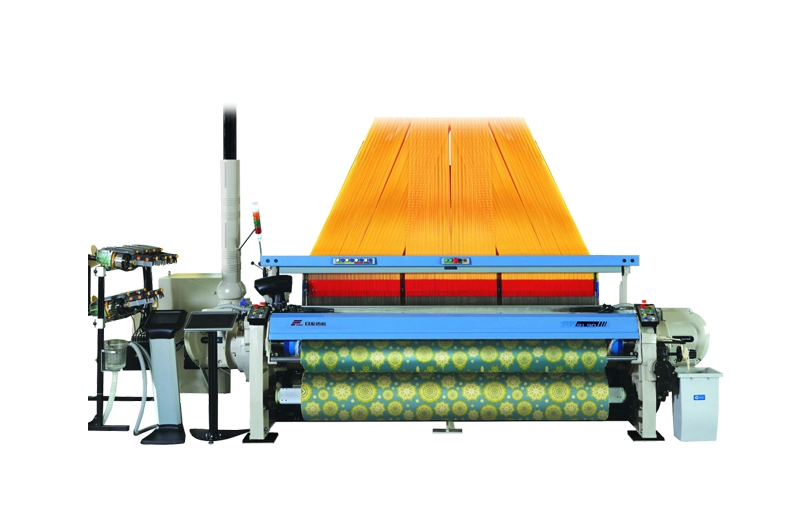

Conventional mechanical spindle twisters rely on gear-driven systems, which consume more energy and often cause yarn damage due to friction. RIFA's electric-drive single twister machine replaces mechanical transmissions with direct-drive technology, reducing energy consumption by over 30%. It features a unique dynamic balancing system—developed in collaboration with Zhejiang University—that automatically adjusts for spindle speed deviations, ensuring consistent twist levels. This is particularly beneficial for producing high-quality cotton, synthetic, and blended yarns.

How the RFTI11 Electric Spindle Twister Achieves "Zero Breakage" and Energy Savings?

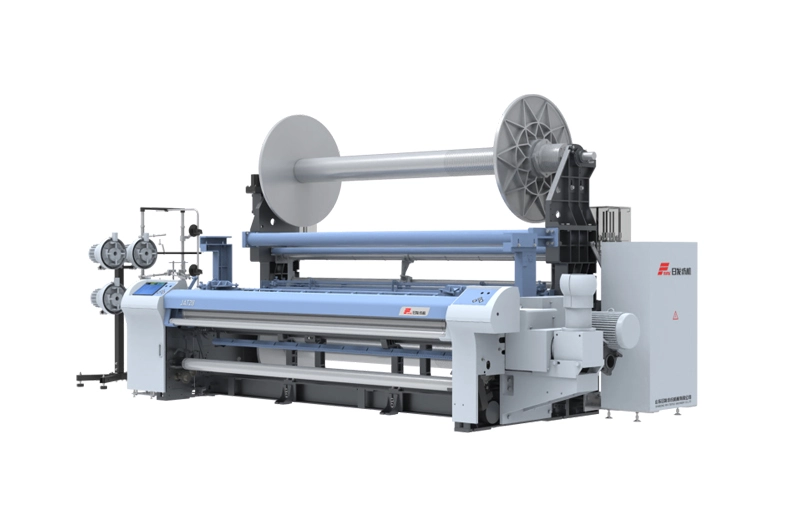

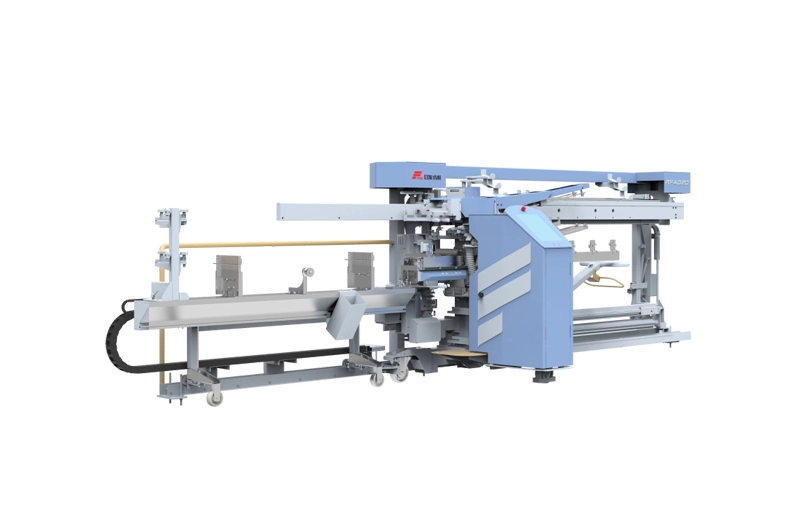

The RFTI11 model, one of RIFA's flagship products, stands out with several advanced features:

A Schneider smart control system that dynamically regulates spindle speed to prevent over- or under-twisting.

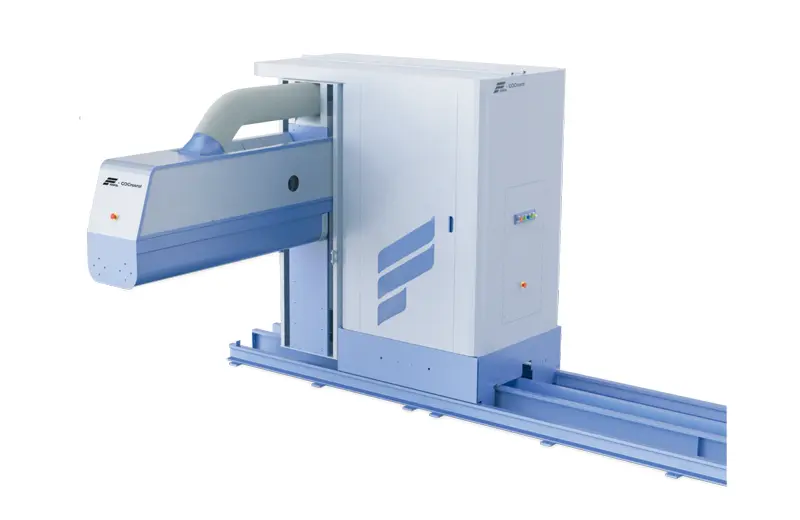

Siemens servo motors paired with Uster quality monitoring modules that detect yarn defects with up to 99.7% accuracy.

A modular machine design that allows quick batch changes and minimizes downtime.

Can a Single Twister Machine Really Reduce Costs?

Many textile mills question the return on investment before upgrading equipment. Rifa addresses this with concrete data:

Energy efficiency: The electric spindle model consumes 35% less energy per unit of output than traditional mechanical machines.

Labor savings: Its automatic yarn joining system cuts manual intervention by 60%.

Lower maintenance: An enclosed spindle rail design reduces lubricant usage and lowers annual maintenance costs by 40%.

According to lifecycle cost (LCC) modeling developed with the Chinese Academy of Sciences, most Rifa machines achieve payback in under 18 months.

From Vietnam to India: RIFA's Global Adaptability

RIFA has optimized the RFTI11 for high-temperature, high-humidity regions such as Southeast Asia by enhancing rust resistance, cooling efficiency, and voltage compatibility (180V–480V). Even in areas with unstable power supply, like parts of India, the machine operates stably.

Which Single Twister Machine Fits Your Factory? RIFA Offers Tailored Support

Yarn count and material type—whether cotton, polyester, or Tencel—affect twisting requirements. With technical backing from Donghua University's School of Textile Engineering, RIFA offers free yarn sample testing. Customers can send yarn samples, and RIFA's lab will determine optimal spindle speed and tension settings, then generate a customized report. To learn how equipment upgrades can help meet Uster yarn quality standards or to explore local after-sales support, contact Rifa's expert team today.

English

English  français

français  Español

Español  русский

русский  português

português  Türkçe

Türkçe  العربية

العربية  한국어

한국어  فارسی

فارسی  Malay

Malay