In the textile industry, yarn quality directly affects the final fabric's feel, strength, and appearance. How can manufacturers ensure consistent twist, stable strength, and reduced hairiness in yarns? The application of the modern textile twisting machine has become key. As a high-tech enterprise with nearly 30 years of innovation, Rifa Textile Machinery has developed a new generation of high-efficiency twisting equipment, offering leading solutions to textile manufacturers worldwide.

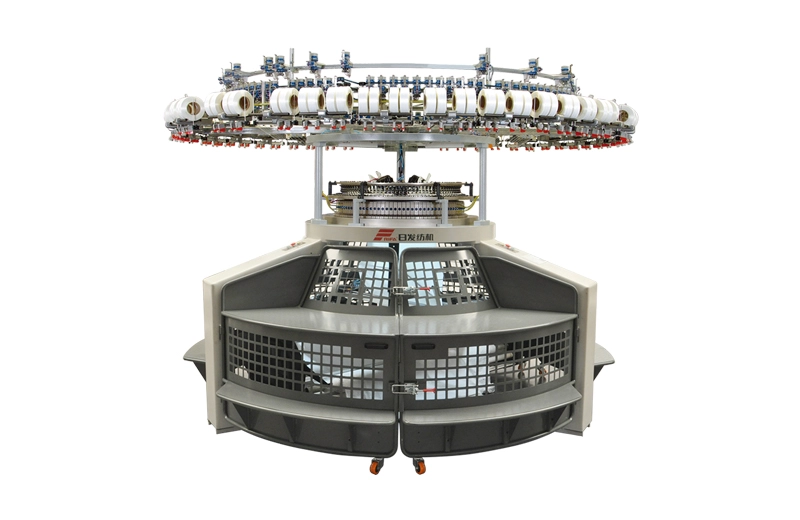

High-Precision Twisting: Ensuring Uniformity in Every Yarn

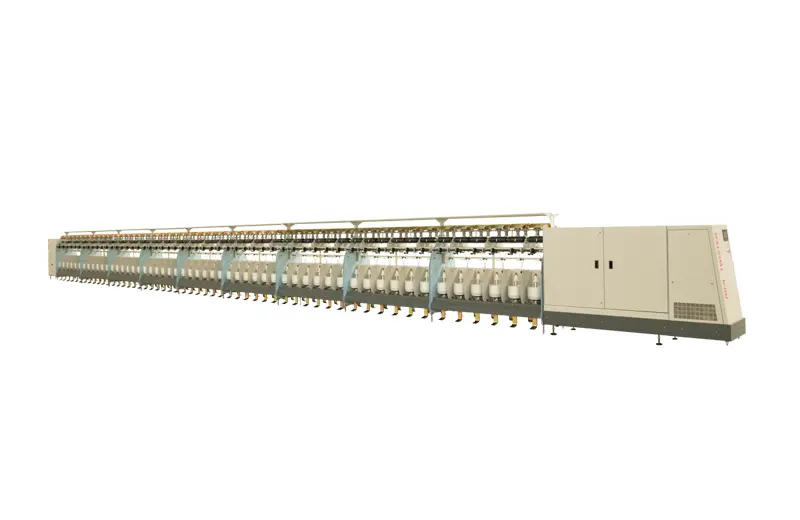

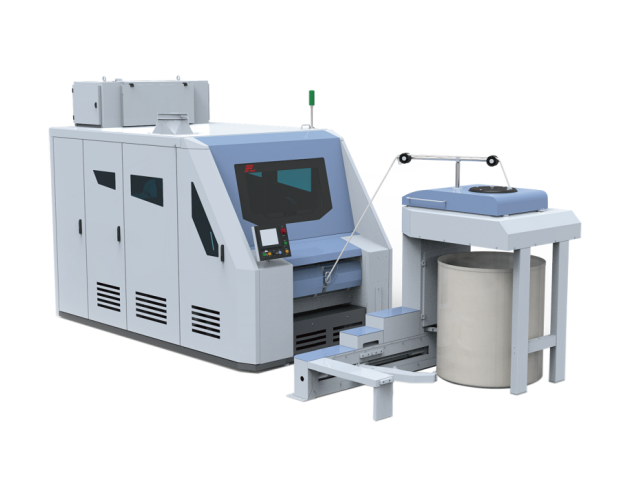

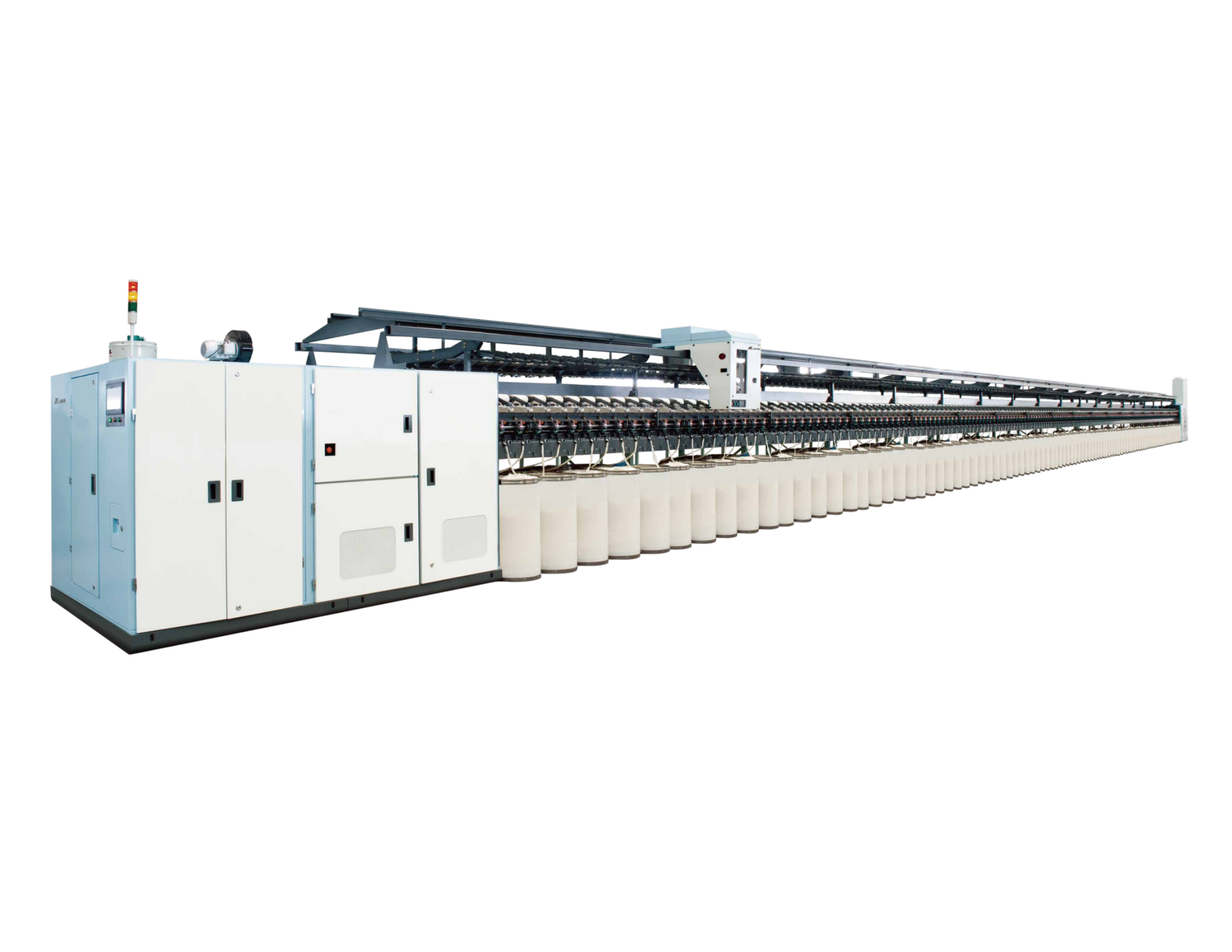

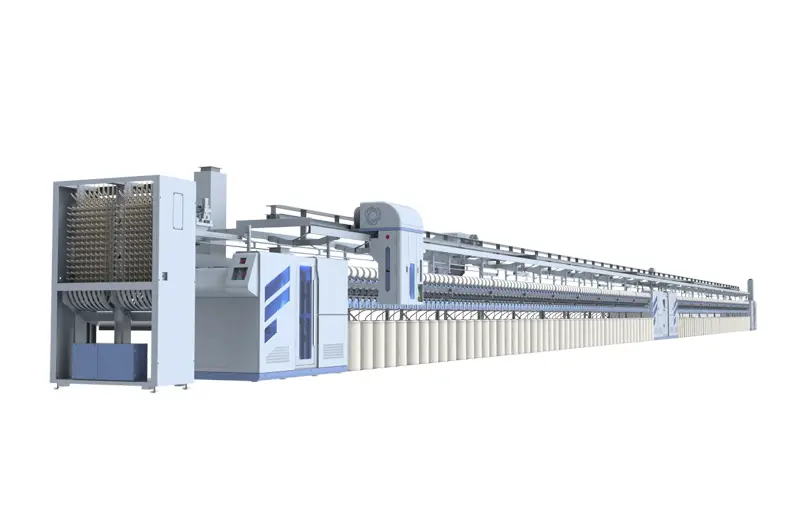

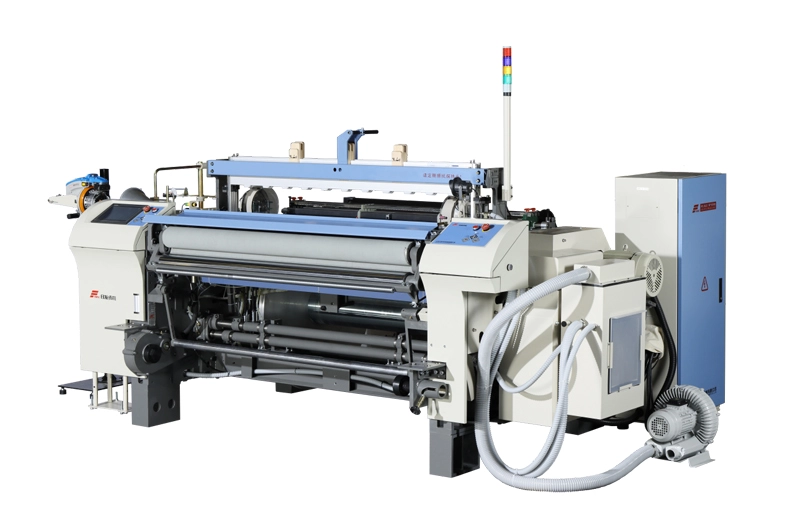

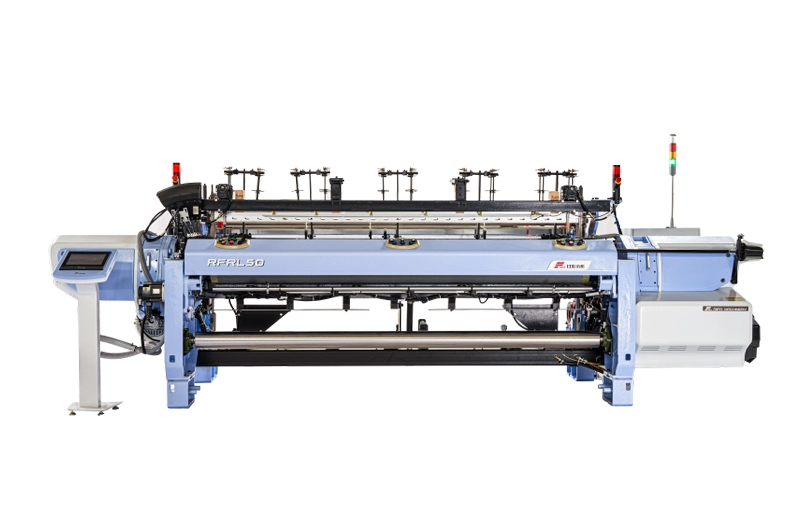

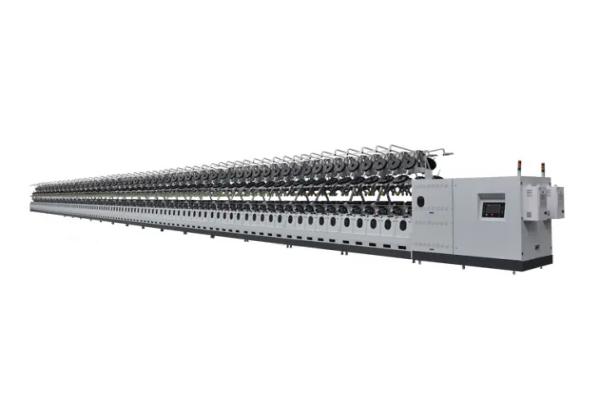

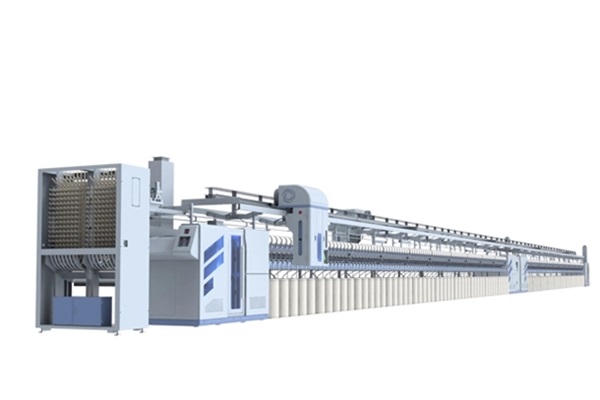

Rifa's textile twisting machine is equipped with an advanced servo control system that ensures consistent tension during the twisting process. Unlike traditional mechanical twisters, modern machines digitally regulate twist parameters, minimizing human error and significantly reducing the yarn's coefficient of variation (CV%) in twist. For example, the RFTF20D model, co-developed with Siemens, maintains stable operation from yarn feeding to delivery, making it ideal for high-end apparel and industrial textiles.

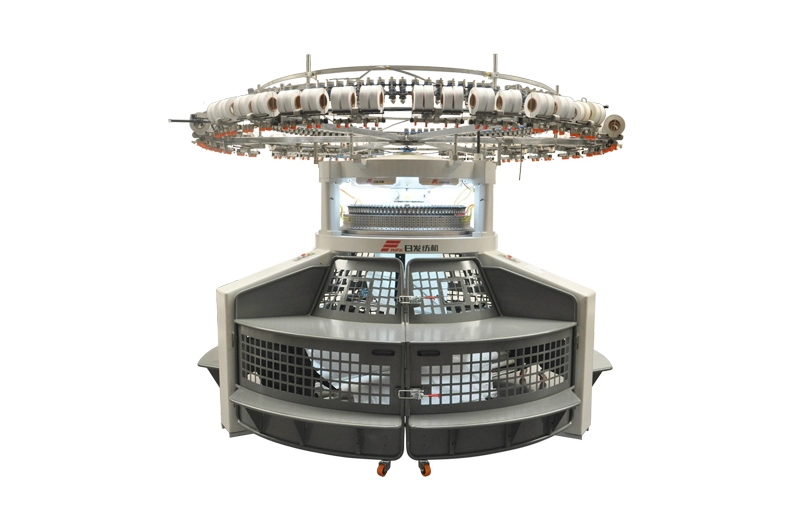

Smart Yarn Break Detection: Reducing Waste and Improving Yield

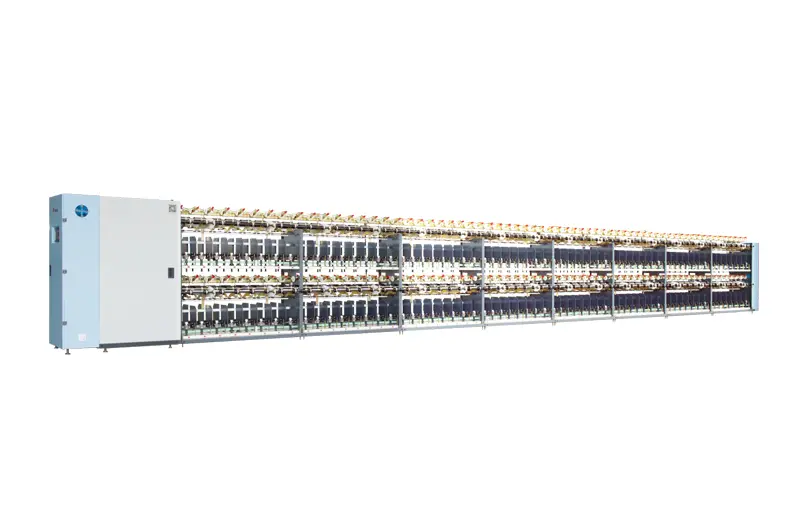

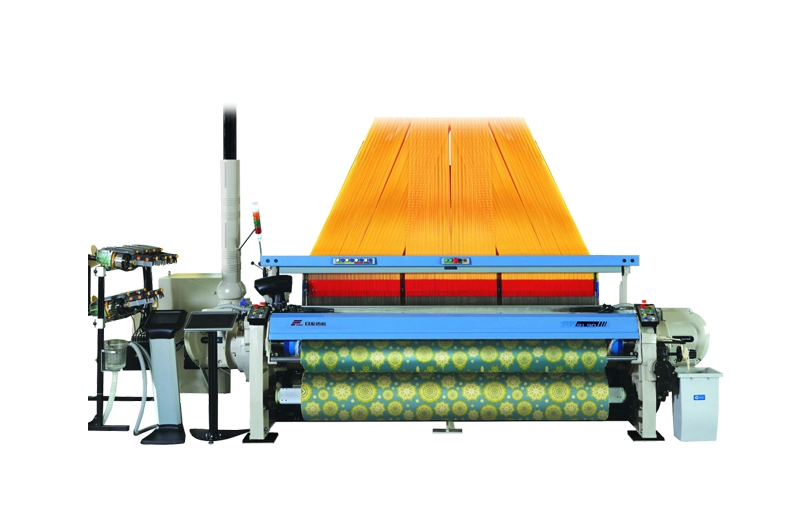

Yarn breaks during twisting can lower production efficiency and compromise quality due to joint issues. RIFA's two-for-one twister integrates a USTER® quality monitoring module that detects breaks within 0.1 seconds and triggers automatic stop. Combined with an innovative self-cleaning yarn guide system, the machine reduces fiber hairiness and ensures the final yarn is smooth and consistent.

Modular Design: Adapting to Diverse Fiber and Product Demands

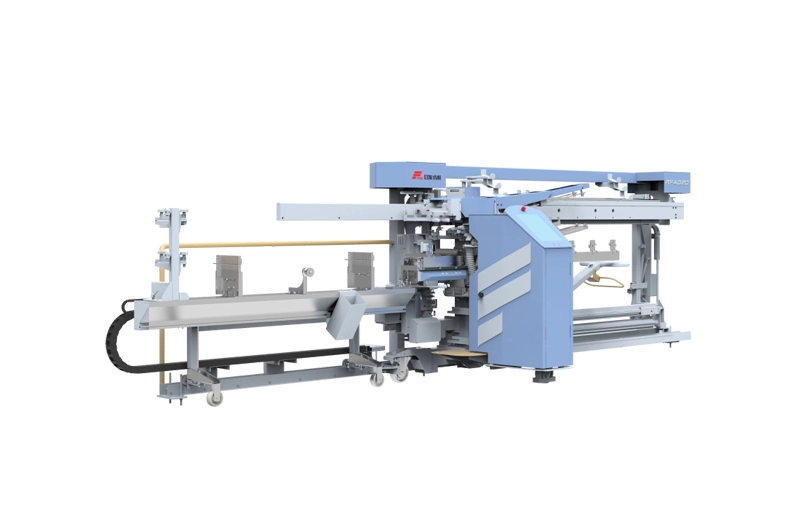

Different fibers—such as cotton, polyester, spandex, and carbon fiber—require varied twisting processes. Rifa's machine offers interchangeable ceramic and steel ring components, allowing users to quickly adapt to production needs. A special twisting module, co-developed with Donghua University, enables efficient processing of ultra-fine denier and blended yarns, meeting the growing demand for customized textile solutions.

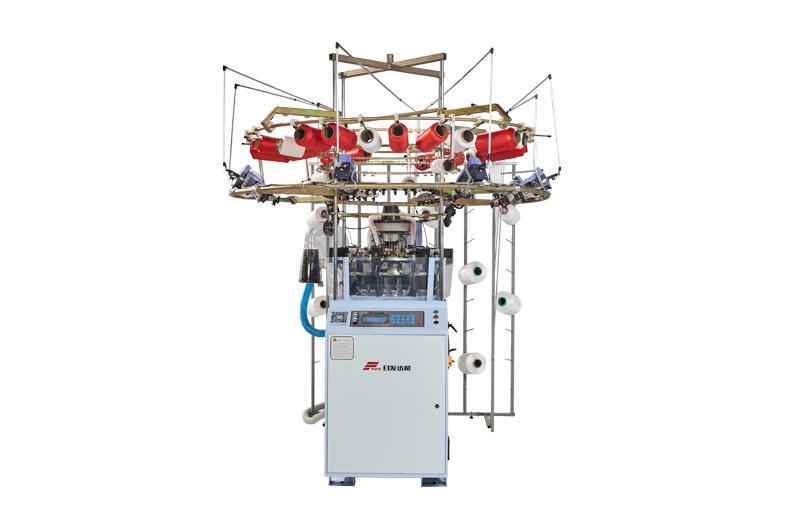

Energy-Saving Technology: Lowering Costs, Enhancing Competitiveness

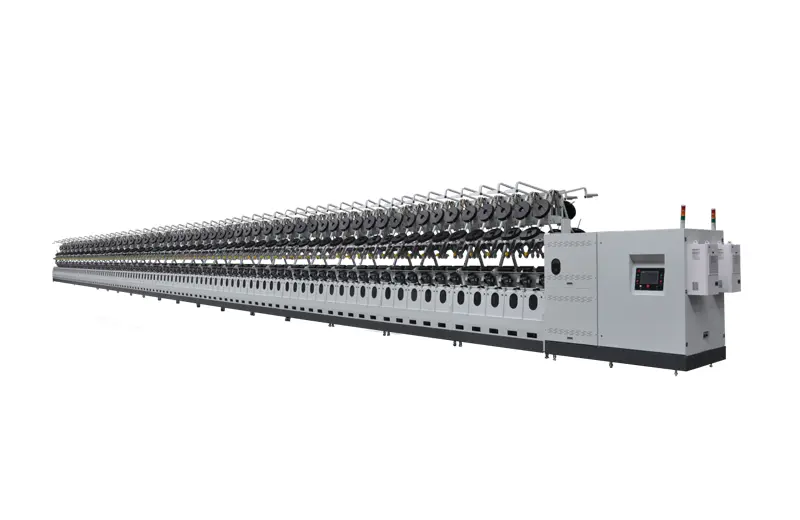

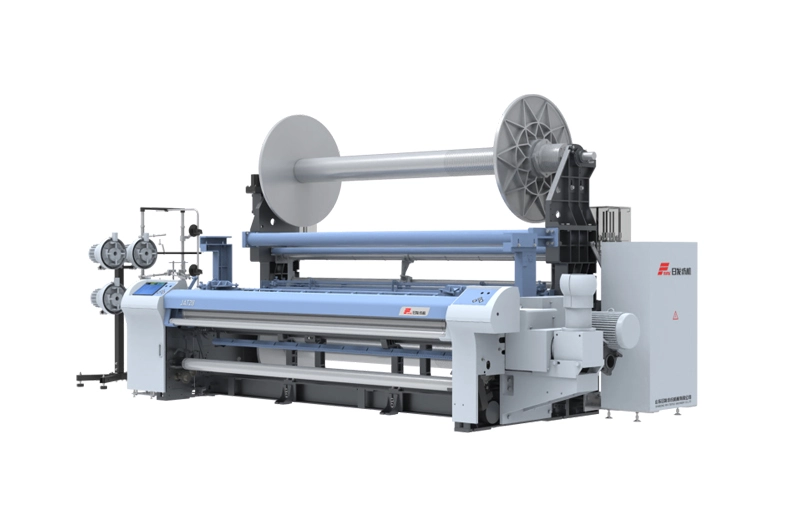

Traditional twisting machines are energy-intensive. Rifa addresses this by optimizing mechanical structures and incorporating Schneider energy-efficient motors, reducing energy consumption by over 30%. Its innovative airflow guide system minimizes friction loss, and variable frequency drive technology ensures productivity while cutting electricity use.

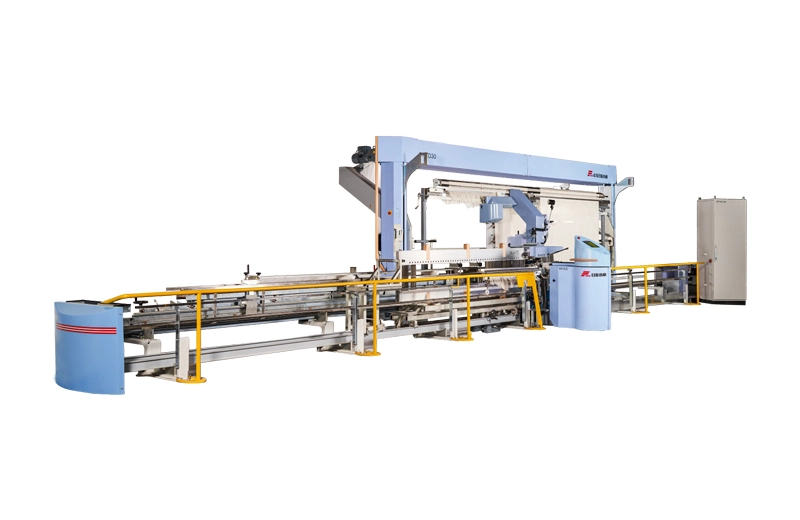

CIMS Integration: The Digital Future of Yarn Production

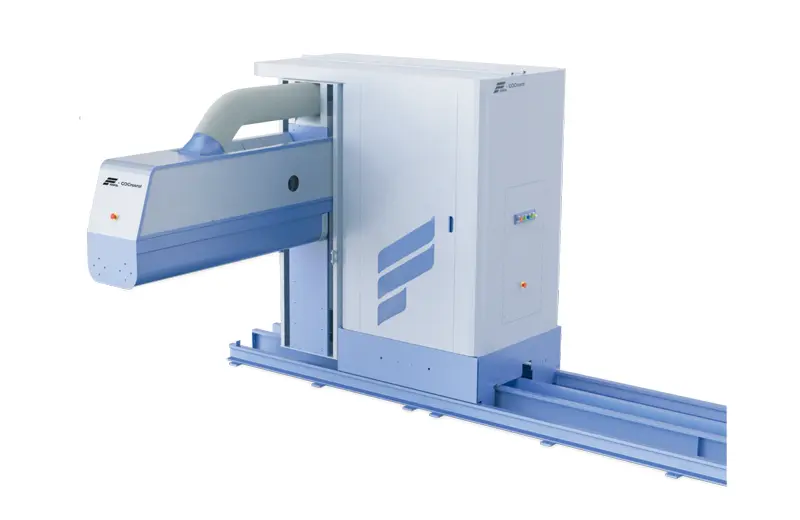

As an implementer of Computer Integrated Manufacturing Systems (CIMS), RIFA connects its textile twisting machine to enterprise-level MES systems, enabling real-time monitoring and data analysis. Factory managers can check machine status, output, and alerts via mobile devices—making "dark factories" a reality. This smart manufacturing model has already been adopted by clients in Vietnam, India, and beyond, helping them respond quickly to high-end order demands.

Modern two-for-one twister machine has evolved from mechanical devices into intelligent systems that combine sensor technology, IoT, and energy-saving design. With strong partnerships—including the Chinese Academy of Sciences and leading global companies—RIFA continues to drive industry innovation. If you are seeking a stable, efficient, and low-consumption twisting solution, feel free to contact us for tailored machine recommendations.

English

English  français

français  Español

Español  русский

русский  português

português  Türkçe

Türkçe  العربية

العربية  한국어

한국어  فارسی

فارسی  Malay

Malay